Why PLG Supplies Are Crucial in Today’s Just‑In‑Time Logistics Model

In today’s world of instant shipping, hyper-lean warehouses, and real-time delivery, supply chains are no longer built for bulk — they’re designed for precision. The rise of the Just-in-Time (JIT) logistics model has transformed how businesses operate, shifting focus from stockpiles to synchronization.

In this increasingly complex landscape, PLG supplies have emerged as the hidden backbone of operational continuity. These are the fasteners, filters, safety gear, fittings, tools, and maintenance essentials that don’t always grab headlines—but absolutely keep the machine running. When a company can’t afford to wait even a day for replacement parts or routine supplies, the right PLG partner becomes priceless.

Let’s explore why plg supplies are no longer a background player, but a core pillar in successful modern logistics.

What Are PLG Supplies? And Why Do They Matter?

The term “PLG supplies” typically refers to procurement-level goods—the essential consumables and operational tools used across facilities, construction sites, manufacturing plants, and distribution hubs. Think:

- Plumbing and HVAC fittings

- Safety equipment (gloves, eyewear, vests)

- Cleaning and maintenance products

- Mechanical fasteners, clamps, seals

- Electrical hardware and utility tools

They may seem small in scope, but in reality, these items enable day-to-day functionality. Without them, even the most technologically advanced infrastructure comes to a halt.

In Just-in-Time logistics, where every delay is magnified, plg supplies become the front line of continuity.

The Just-in-Time (JIT) Logistics Model — Explained

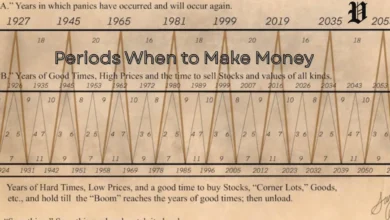

JIT logistics is a supply chain philosophy where inventory arrives exactly when it is needed—no sooner, no later. The goal is to reduce waste, limit holding costs, and keep operations lean. But this approach requires near-perfect coordination between vendors, warehouses, delivery teams, and internal inventory systems.

With JIT, there’s no room for slow or unreliable suppliers. This is where the agility and reliability of plg supplies providers make the difference between seamless operations and costly downtime.

Table: Traditional Inventory vs. PLG Supplies in JIT Systems

| Attribute | Traditional Inventory Model | PLG Supplies in JIT Logistics |

|---|---|---|

| Storage Method | Warehoused in bulk | Minimal inventory; just-in-time |

| Supplier Engagement | Periodic reordering | Continuous micro-procurement |

| Role in Production | Often core raw material | Indirect but mission-critical |

| Visibility in ERP Systems | Fully mapped | Often untracked or manually managed |

| Delay Impact | Moderate | High — can halt key tasks |

The Cost of Overlooking PLG Supplies

Let’s put it in perspective.

Imagine a large-scale manufacturing facility producing HVAC systems. The core components—fans, coils, motors—are delivered on time, but the assembly grinds to a halt because a shipment of mounting brackets or sealant tape is delayed.

This small oversight leads to:

- Lost production hours

- Rescheduled labor

- Missed client delivery windows

- Ripple effects across the supply chain

All because plg supplies weren’t prioritized. In JIT logistics, the cost of ignoring the “small stuff” quickly becomes massive.

Why PLG Supplies Providers Are Strategic Partners, Not Vendors

Smart companies have begun to rethink their relationships with plg supplies providers. No longer seen as basic procurement vendors, these suppliers are now treated as strategic allies in resilience and flexibility.

Characteristics of High-Value PLG Supply Partners:

- Same-day or next-day delivery options

- Inventory forecasting tools based on usage

- Integration with warehouse management systems

- Dedicated account managers for procurement consistency

- Emergency order fulfillment for unplanned needs

In the JIT model, you don’t just buy products—you invest in uptime.

How PLG Supplies Enhance Flexibility in Operations

The world has moved beyond static workflows. Today, a facility manager may scale up operations one week and shift into maintenance mode the next. Construction timelines pivot rapidly due to weather, labor, or funding.

Plg supplies serve as the “fluid currency” that allows operations to flex without breaking. A reliable supplier ensures the right materials are always within reach, even in fluctuating environments.

Real-World Examples:

- Data centers that rely on plg supplies for emergency cooling repairs

- Retail logistics hubs that consume thousands of gloves, straps, and labels weekly

- Facility managers who need instant access to caulk, fittings, and PPE to pass compliance audits

Without a strong plg pipeline, these real-time decisions become friction points.

Technology’s Role: Digitizing PLG Supply Chains

To meet the demands of JIT logistics, leading plg supplies providers now integrate with digital platforms.

- Automated Replenishment Systems: Track consumption and auto-order when thresholds are met

- Mobile Procurement Apps: Let field teams order supplies without delays

- IoT Integration: Monitor tool usage, fluid levels, and wear to predict future needs

- Data Dashboards: Provide spend analysis and procurement reporting

This digital transformation doesn’t just streamline operations—it delivers predictability, the true currency of JIT systems.

FAQs: PLG Supplies and Just-in-Time Logistics

What exactly qualifies as “PLG supplies”?

Typically, these are small, essential items used regularly in operations—plumbing parts, safety gear, electrical accessories, and industrial consumables.

Why are they so important in JIT logistics?

Because JIT leaves no room for stockpiling, the timely availability of plg supplies is critical. Even one missing component can stop an entire workflow.

Can plg supplies be managed digitally?

Yes. Many suppliers now offer digital integration, inventory tracking, and even predictive ordering systems to keep your supply chain lean but reliable.

What industries rely most on PLG supplies?

Construction, manufacturing, logistics hubs, data centers, facility management, and healthcare—anywhere that depends on consistent operations with minimal buffer.

Conclusion: Small Parts, Big Performance

We often associate innovation with big, shiny upgrades—automation systems, robotics, and AI dashboards. But in truth, the smoothest-running operations are often powered by precision in the margins.

In a Just-in-Time world, there’s no such thing as a minor supply. The clamps, gloves, and connectors that arrive on time are what keep businesses in motion. PLG supplies are no longer secondary—they are mission-critical.

As supply chains evolve, success will belong not just to those who innovate at scale—but to those who manage the details with care. And at the heart of those details? A well-oiled, always-on, responsive plg supplies network.